ISO 9001:2015, ISO 13485:2016 certified, Comply with international quality inspection standards ISO2768-m, ISO2768-k

Quality is the premise of all long-term development. Pay attention and contact us. Our quality is your partner for success.

We adhere to the principle that quality is the life of the enterprise, and our quality has always been the primary factor for long-term cooperation with customers.

Our quality inspection

2015

ISO 9001 CERTIFIED

100+

CNC machines

10K+

CNC machined parts/ month

100+

Plastic & metal materials

Our quality inspection process and system

Our quality management covers the entire project process, from inquiry to delivery.

Order review:

After receiving the customer's order, we start double independent, engineering to ensure the manufacturability of each step of the part, manufacturing design review (DFM), comprehensive evaluation of all projects, and then send it to the production department for another review, production capacity and production plan review (PMC), to ensure that the size, material, tolerance, surface treatment, quantity and delivery date meet the order requirements.

Raw material inspection:

All raw materials are strictly inspected for quality before entering the warehouse to ensure that they meet the standards. And provide relevant material certificates according to customer requirements

Production process monitoring (IPQC):

During the production process, real-time monitoring is implemented to ensure that each link meets the quality standards.

First piece inspection:

After the first piece of the product is completed, the first piece inspection (FAI) is carried out. If the inspection is qualified, production will continue. If it is unqualified, production cannot be carried out. First article inspection report can be provided according to customer requirements.

Intermediate inspection:

Intermediate inspection is carried out at key production stages to detect and correct potential problems in a timely manner

Final inspection and test report (FQC):

Comprehensive final inspection is carried out after the product is completed to ensure that all products meet the specifications and provide customers with a final inspection report.

Testing and verification:

All quality control processes are carefully documented to ensure traceability and consistency.

Quality management system

Customers' comments on our product quality

Application of quality inspection

Gallery of Our Quality Inspection

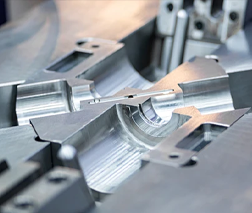

Process: CNC turning+ milling

Material: stainless steel 316

Tolerances: ⌖0.05mm

Finishes: As machined (Ra0.8μm/1.6μm)

automation-cnc-turning--stainless-steel-joint--rod

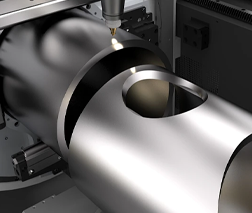

Process: CNC turning

Material: stainless steel

Tolerances:◎ 0.05mm;

Finishes: Bead blasted, Clear anodized

automation-machine-aluminum-cnc-machining-cooling-plate

Process: CNC milling

Material: aluminum alloy

Tolerances: //0.2; ⌖0.05mm

Finishes: Bead blasted, Clear anodized

5-Axises-CNC-Machining-Metal-Precise-and-Complex-Prototypes

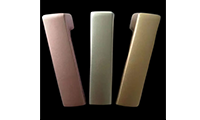

Process: CNC milling

Material: aluminum alloy

Tolerances: ISO 2768-m

Finishes: As machined 1.6μm

cnc-turning-aluminum-part-motor-front-cover

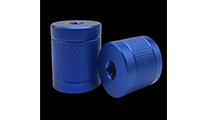

Process: CNC turning + milling

Material: aluminum 6061

Tolerances: ISO 2768-m

Finishes: Bead blasted, Clear anodized

Custom-Cnc-Mechanical-Aluminum-Plate

Process: CNC milling

Material: Aluminum 5083

Tolerances: ISO 2768-F

Finishes: Polishing

custom-non-standard-stainless-steel-cnc-parts-precision-shaft

Process: CNC turning + milling

Material: stainless steel 304

Tolerances: H6(0.016mm); h6(0.025mm); G5(0.018mm); ⌖(∅0.2mm)

Finishes: As machined Ra0.8μm

high-persion-aluminum-cnc-machining-medical-parts

Process: CNC milling

Material: aluminum 7075

Tolerances: ISO 2768-F, ▱ 0.1mm

Finishes: Polishing

Our quality management principles

Standardized management

Adopt advanced management concepts, establish clear work processes and operating standards, cultivate a skilled, professional and efficient team, and improve production efficiency and quality.

Customer First

With customer needs and satisfaction as the core, optimize production plans, processes, supply chain management, and strictly control costs. Continuous improvement, pursuit of excellent quality, to ensure maximum satisfaction of customer expectations

Quality First

Implement a comprehensive quality management system, from raw material procurement to finished product delivery, every link is strictly controlled to ensure high standards and consistency of products.

Innovative Development

Build a learning organization and promote knowledge sharing. Collect and organize knowledge resources from various fields to provide employees with a growth platform. Encourage innovative thinking, create effective, better and more efficient methods and solutions, and enhance the core competitiveness of the enterprise.

Common Quality Control Processes

| name | Can BeApplled with | ||

|---|---|---|---|

|

Anodizing | Anodizing is an electrolytic process used primarily for the treatment of aluminum and aluminum alloys. In this process, the metal is placed in an electrolyte as an anode, and an electric current is passed through the metal surface to form an oxide film. |

|

|

Sand Blasting | Sandblasting is the process of using abrasive particles ejected at high pressure and at high speed to remove the oxide layer, rust or old coating on the surface, making the rough surface smooth and improving the adhesion of subsequent coatings. |

|

|

Powder Coating | Powder Coating is an electrostatic spraying technology that charges the powder coating and adsorbs it on the surface of the object. After high-temperature baking, the powder melts and fixes on the object. |

|

|

Painting | Painting is the process of spraying liquid paint evenly on the surface of an object in a mist form through a spray gun to form a smooth coating. One or more layers of paint are applied to the surface to provide protection, decoration or special functional coatings. |

|

|

Electroplating | Electroplating is a process that uses the principle of electrolysis to plate a thin layer of other metals or alloys on the metal surface, such as nickel, chromium (chroming), zinc (Galvanizing), silver, rose gold, etc. |

|

|

Silk printing | Silk printing, Silk screen printing, full name screen printing, screen printing is a printing technique that uses a mesh-like screen to transfer ink to the surface of various materials. |

|

|

Knurling | Knurling is a manufacturing process,typically conducted on a lathe, whereby a patterm of straight,angled or crossed lines is rolled into product surface. |

|

|

Gilding | Gilding is an ancient decorative technique that involves applying a thin layer of metal, usually gold or silver foil, to the surface of various materials to give them a unique beauty and a regal appearance. |

|

|

Grinding | Grinding is a common surface treatment process. Its purpose is to remove irregularities, burrs, rust or other defects on the surface of the material by physical or chemical means to make the surface smoother, flatter and cleaner. |

|

|

Polishing | Polishing is a processing method that uses abrasive particles or other polishing media and flexible polishing tools to remove fine scratches and flaws on the surface of the workpiece. |

|

|

Wire Drawing | The main purpose of wire drawing is to form lines on the surface of the metal workpiece by physical grinding, reflecting the texture of the metal material and playing a decorative effect.Wire drawing is widely used. |

|

|

Passivation | Passivation is a process that uses strong oxidants or electrochemical methods to cause an oxidation reaction on the metal surface, remove iron ions on the surface, form a dense passivation film, and thus improve the corrosion resistance of parts. |

|

|

Heat Treatment | Heat treatment process is to heat the workpiece to an appropriate temperature in a certain medium, keep it at this temperature for a certain period of time, and then cool it at different speeds in different media to control. |

|

|

Chemical conversion coating | A chemical conversion coating is a layer of film formed on a metal surface by a chemical reaction. This layer is usually a stable compound formed by the reaction of the metal with a specific chemical treatment solution. |

|

|

Bluing | Bluing is a chemical oxidation treatment process for metal surfaces. Its purpose is to improve the rust resistance of metals (especially steel) and give the metal surface a blue protective film. Bluing treatment is usually carried out at a higher temperature, about 550°C. |

|

|

Blackening | Blackening is also a chemical oxidation treatment process for metal surfaces. Blackening is carried out at a lower temperature, usually between 130°C and 150°C, to form a black oxide film. |

|

|

laser engraving | Laser engraving is a process that uses a high-energy laser beam to precisely cut, mark or engrave the surface of a material. This technology can be performed on a variety of materials, including but not limited to metal. |

|

|

Vapor Polishing | Vapor polishing is a surface treatment process used to improve the transparency and gloss of plastic parts. This technology uses a chemical vapor phase, usually a pressurized air flow. |

|

|

texture | texture, It mainly uses chemical solutions to create various patterns on the surface of different metal products. It can not only enhance the appearance and texture of the product, but also improve the functional properties of the product. |

|

|

Plastic coating | Plastic coating is to wrap a layer of soft rubber on the surface of hard Workpiece to make them feel textured. The core is to use the unique properties of silicone to evenly wrap silicone rubber on the surface of other materials. |

|

|

Dyeing | Dyeing is a process of immersing product pieces in a dye solution that has been matched to the customer's desired color, thereby changing the color of the product. This treatment can enhance the product's appearance, durability, and provide certain protective effects. |

|

|

CHROMATE oxidation | CHROMATE oxidation is indeed a chemical conversion coating treatment technology. The main components of the chromate conversion coating are compounds of trivalent chromium and hexavalent chromium, as well as chromate salts of the base metal. |

|

|

Bead blasting | Bead blasting is a surface treatment process, a type of sandblasting. It uses high pressure to propel small beads (usually spherical particles made of glass, ceramic or metal) against the surface of a material to clean or change its surface texture. |

|

|

water transfer printing | Water transfer technology is a printing technology that uses water pressure to transfer the transfer paper/plastic film with colored patterns to the surface of products of various shapes through the force of water. |

|

|

Brushing | Brushing technology is the use of abrasive brushes or pads to create a textured surface, thereby improving the visual appeal and functionality of the material. Brushing can produce straight lines or specific patterns of textures. |

|

|

Vacuum Metalizing | Vacuum Metalizing is a physical vapor deposition (PVD) technology that forms a metal film by evaporating and depositing metal onto a non-metallic substrate in a vacuum environment. |

|

|

Hand Finishing | At Brightstar, we have a group of skilled workers who perform a series of post-processing by hand. This process involves the meticulous modification and perfection of parts or products to ensure that they meet the design specifications and functional requirements. |

Quote Now to Start Your Quality Control Project

CNC machining tolerances

Brightstar ensures that your project is built on a safe and reliable basis. Choose Brightstar and start a new quotation

FAQ on Quality Inspection

FAQ on Quality Inspection

Third-party quality inspection refers to quality inspection conducted by a third-party organization independent of manufacturers and consumers.

- Use calibrated inspection equipment,Every year we invite a third party to carry out our testing tools and quality system calibration

- Regularly train inspection personnel

- Follow standardized inspection procedures

- Perform double checks or quality control

When choosing inspection equipment, you need to consider the accuracy, reliability, ease of use and cost-effectiveness of the inspection.

Blogs