Brightstar: Leading Medical Rapid Prototyping for 17 Years. Specializing in Food-Grade & Production-Grade Materials for Quality Prototypes & Fast Manufacturing. Simplify Your Process – Contact Us Today!

Medical Prototyping and Part Manufacturing

Importance of Prototyping Medical Devices and On-Demand Manufacturing

Prototyping and rapid manufacturing play a vital role in the field of medical devices. They not only accelerate the pace of product development from concept to commercialization, but also allow manufacturers to validate and iterate designs at an early stage to ensure that the product is fit for purpose solutions and industry standards. This approach helps reduce R&D costs and improve production efficiency, while enabling manufacturers to collect valuable user feedback and make adjustments to optimize the final product, allowing them to quickly enter the laboratory or clinical trials and ultimately get to market faster. In addition, rapid prototyping supports the development of personalized and customized products to meet the needs of specific patient groups, promote medical innovation, and improve patient treatment outcomes.

Brightstar Rapid Prototyping and On-Demand Manufacturing Services

Brightstar, as one of professional medical device prototyping companies in China, has relied on many years of experience in prototyping and manufacturing in the field of medical devices, using advanced rapid prototyping technology and digital manufacturing processes to provide high-performance prototypes and components for the medical device industry. Focusing on the production of medical device prototypes, from simple to complex medical devices, medical device components, from early prototypes to final parts, Brightstar's advanced manufacturing technology and quality control team are committed to providing ultimate solutions for a variety of medical devices. Through its expertise and innovative capabilities in the field of medical device prototypes, Brightstar ensures that every link from design to production meets the strict requirements of the medical industry.

Why Cooperate with Brightstar? Our Manufacturing Advantages:

- Advanced 5-axis CNC machining (tolerance: ±0.005mm) and 3D printing for rapid prototyping and complex part manufacturing.

- Use biocompatible materials, wide range of medically suitable materials like titanium and silicone.

- ISO 9001:2015 certified with strict quality control, supported by CMM and full inspection processes.

- Our skilled engineering team ensures optimal design and manufacturing process to ensure cost efficiency in medical development.

- 17+ Years of Expertise

- Capable of handling orders of any size, from rapid prototype to mass production.

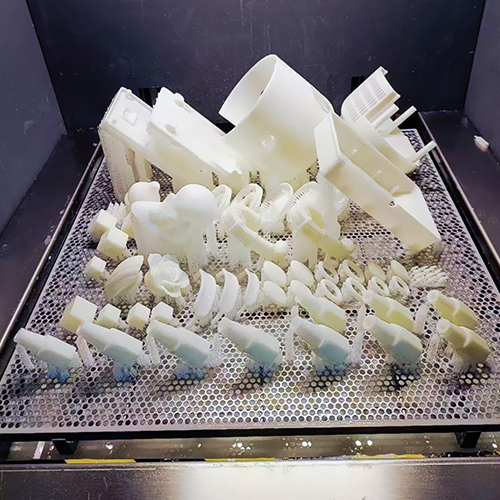

Rapid Prototypes We Made in The Medical Industry

The medical and healthcare industries require a wide range of parts and prototypes made from a variety of materials. These include parts that are expected to come into contact with the human body, as well as parts in machinery and equipment used by medical professionals. Typical requirements include: Tight tolerances for critical components and assemblies Biocompatible, non-toxic or sterilizable materials Quality control through in-machine inspection and/or CMM

Medical Device Prototypes and Precision Parts We Can Machine

Diagnostic and imaging equipment:

Including MRI and X-ray components, diagnostic equipment, ultrasound equipment, etc., for medical image acquisition and disease diagnosis.

Therapeutic equipment:

Covering surgical instruments, surgical tools, radiotherapy equipment, physical therapy equipment, etc., used to perform therapeutic procedures.

Monitoring and life support equipment:

Including heart rate monitors, ventilators, infusion pumps, monitors, etc., used to monitor patients' vital signs and provide necessary life support.

Rehabilitation and assistive devices:

Including prostheses, orthotics, wheelchairs, rehabilitation training equipment, etc., used to help patients restore physical functions or improve their quality of life.

Laboratory and clinical analysis equipment:

Including blood analyzers, biochemical analyzers, microbial culture equipment, gene sequencing equipment, etc., used for analysis and research of clinical samples.

At Brightstar, we offer medical-specific material and finish options that meet specific biocompatibility, safety, and functionality requirements.

Stainless steel;Titanium and its alloys;Polyetheretherketone (PEEK)

Silicone rubber;Polytetrafluoroethylene (PTFE);Polycarbonate (PC);ABS plastic

In addition to material selection, we also provide a variety of advanced surface treatments suitable for the medical industry, common ones are, anodizing, sandblasting, grinding and polishing, glass bead spraying, spraying (matte, high gloss, texture), electroplating (galvanizing, chrome plating (satin and gloss), nickel plating), laser marking, ultraviolet (UV) curing

Our Customers’ Reviews

You will find out which process best meets your needs and fits your product definition.

Streamline medical device development through best practices in rapid prototyping.

Concept Proof and Design Phase:

Proof of Concept: In this phase, the basic functionality and feasibility of the product are established by building a proof of concept prototype to ensure that the product idea is technically and theoretically feasible.

Visual Presentation: Communicate design intent with stakeholders through visual models and collect feedback to iterate and improve the design.

Prototype Development and Testing Phase:

Functional Prototyping: Develop functional prototypes to test the shape, fit and function of the product, iterate the design to optimize product performance, and discover and solve problems early in product development.

Engineering Validation: Create engineering prototypes to verify design, engineering and manufacturability, ensure the feasibility of the product at the technical level, and discover potential manufacturing problems before mass production.

Pilot Production and Market Preparation Phase:

Pilot Production: Bridge the gap between prototypes and mass production through rapid manufacturing and small batch production to ensure that the product can enter the market quickly and economically.

Market Preparation: In this phase, the product is ready to enter the market, including final quality control, regulatory approval, marketing and distribution strategy implementation.

Brightstar's manufacturing capabilities in the medical prototyping and part manufacturing

Brightstar is committed to working with you to ensure the success of your medical device project. Whether you need rapid prototyping, custom devices, or mass production components, Brightstar can ensure fast delivery and high-quality, consistent results.