Whether it is concept verification or engineering testing, from external lighting systems, internal precision components, to functional parts, we rely on advanced rapid prototyping technology to provide you with accurate and efficient prototype and part manufacturing services.

ISO 9001:2015 and IATF 16949 certificated

Automotive Prototyping and Parts Manufacturing

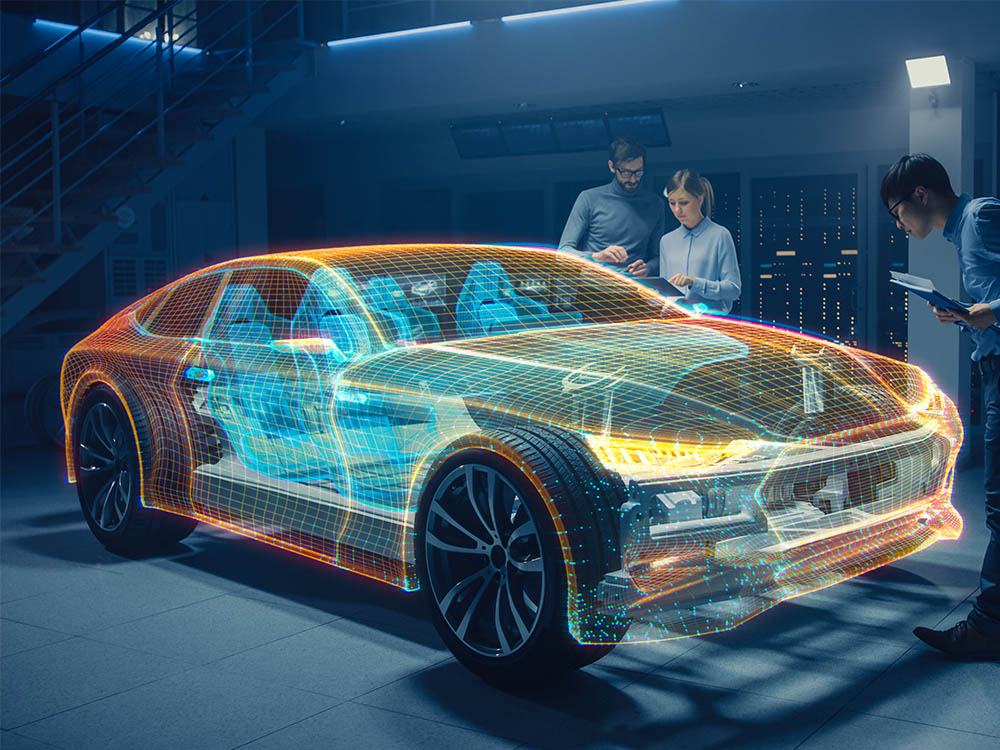

Rapid prototyping accelerates automotive innovation

The rapid development of the automotive industry, especially in the fields of new energy vehicles, autonomous driving technology, intelligent networking, and solid-state batteries, is accelerating the innovation and iteration of the industry towards a more efficient, environmentally friendly and intelligent direction. Automotive rapid prototyping can shorten the time from design to prototype and accelerate the product development cycle. This rapid response capability is essential for innovation and iteration in the automotive industry because consumer needs and preferences are constantly changing.

Automotive prototypes are a fast and effective way to verify concepts, verify functions, verify engineering, and evaluate manufacturing feasibility. Prototypes will help design teams figure out how to make new designs attractive to consumers and prove their value, and how to communicate ideas and iterate designs faster and more effectively with stakeholders and project teams. Prototyping plays a key role in the innovation-driven automotive industry and accelerates the development of the automotive industry.

The technical advantages of Brightstar rapid prototyping in automotive industry

Brightstar has rich experience in automotive prototype manufacturing and parts, as well as custom moto parts manufacturing. With a vast network of our own factory and strong partnerships with Chinese rapid prototyping factories, adheres to the ISO 9001:2015 and IATF 16949 certification standards, it can efficiently deliver complex and high-quality parts. We are good at various types of rapid prototyping technologies, including CNC high-precision machining, 3D rapid printing rapid prototyping, sheet metal, vacuum casting, rapid tools and rapid injection molding. We provide comprehensive and rapid customization services for the automotive industry. Throughout the entire automotive design and development process, we work closely with you. Choosing Brightstar, you will find the prototype manufacturer that best meets your needs and product definition.

CNC machining

Brightstar uses advanced and 5-axis machines to Offer 24/7 precision CNC machining for custom metal and plastic parts, with more than 100 metal materials that can be manufactured, especially machining aluminum is increasing for automotive industry, precision milling and precision turning of aluminum parts. Services include milling and turning with close tolerances and high standards. It is an ideal way for manufacturing needs of complex shapes and precision tolerances.

3D printing:

also known as additive manufacturing, is a technology that builds three-dimensional objects by stacking materials layer by layer. 3D printing provides extremely high design flexibility and can quickly manufacture complex geometries, suitable for prototyping and small batch production. At Brightstar, we provide SLM, SLA, SLS fast printing services, a wide range of material selection, and perfect surface treatment services, which can reliably deliver the parts required by customers within a few days.

Sheet Metal Fabrication:

Involves the process of manufacturing parts using sheet metal materials, including cutting, bending, welding and other steps. This method is suitable for manufacturing metal parts that require a certain strength and shape. At Brightstar, we provide 3D visualization design for manufacturability (DFM) feedback and provide manufacturing suggestions. Our sheet metal projects are up to 1000+/month

Vacuum casting:

The vacuum casting process uses silicone molds to produce polyurethane castings. It is suitable for rapid prototyping and low-volume production at an affordable price. At Brightstar, vacuum casting, small batch global delivery in 10 days or less

Rapid tooling and cost-effective rapid injection molding

Brightstar has many years of experience in rapid tooling for aluminum and steel and plastic injection molding. Aluminum molds can provide cost-effective tools and accelerate manufacturing cycles. We have about 200 different thermoplastic resins and provide a variety of manufacturing solutions and engineering suggestions.

Brightstar serves the automotive industry. Which customers are being served:

Automakers

OEM auto parts factories

OEM auto assembly plants

OEM design studios

Independent OEM auto parts manufacturers

Tier 1 and 2 suppliers

Autonomous driving technology companies

Replacement auto parts manufacturers

Industrial heavy equipment manufacturers

Customers reviews for our prototyping and manufacturing services

Contact us for the right suggestions about prototyping or part manufacturing to match your design requirements

The several important stages of automotive rapid prototyping

In the entire cycle of automotive design and development, automotive prototyping runs through the entire stage of automotive design and development.Through automotive prototyping, manufacturers can quickly iterate designs, optimize performance, and resolve potential issues before actual production. Prototyping makes it possible to produce and customize automotive parts on demand, which is very valuable for innovation and personalized options in the automotive industry.

Concept prototype stage

Designers build models by hand, use reverse engineering technology to scan models to obtain CAD models, and then use digital modeling to explore different design directions and optimize the design. After that, designers and engineers use CAD software to create more detailed designs. Convert the design concept into a model to prove the feasibility of product conceptualization. Through repeated iterations and improvements, the idea is finally turned into the desired physical model. Handmade models are very useful in early concept exploration, and rapid prototyping technology allows designers and engineers to create complex geometric shapes that are difficult or impossible to achieve with traditional manufacturing methods. This design freedom promotes innovation and allows new design concepts to be iterated quickly.

Prototype (or "mule") stage

At this stage, engineers create a series of functional prototypes of the car, which are used to verify the fit of various components in space and ensure that the structural size of the design is reasonable and easy to install. Through these prototypes, engineers can actually observe and test the interaction between components, comprehensively evaluate the feasibility of design solutions, material selection, durability, tolerance range, assembly process, mechanical operation and manufacturability of production, so as to quickly identify and solve potential problems in the early stage of product development.

Engineering Verification

At this stage, it is critical to build an engineering prototype, which combines engineering and design to accurately represent the final product. During this process, further aerodynamic testing, ergonomics, mechanical properties, thermal properties, electrical properties and product life and safety standards testing will be carried out. Engineering test prototypes allow for rapid iteration of designs based on actual testing and feedback to meet the required performance, verification, testing, certification and quality requirements. At the same time, the prototype vehicle is operated in a real environment to test its safety and stability.

Small batch trial production

This is the last stage before starting large-scale production. Small batch trial production verifies the manufacturing process, finds possible production problems and determines the most cost-effective manufacturing process.

Accelerating Your Project with Brightstar's Expertise in Rapid Prototyping

With professional skills, efficient processes and strict quality control in the field of rapid prototyping, Brightstar can speed up your project development and accurately meet your needs. Whether it is automotive exterior optical components, internal mechanical parts, personalized options, or low-volume manufacturing, we can provide professional manufacturing services.