Components of automated mechanical equipment

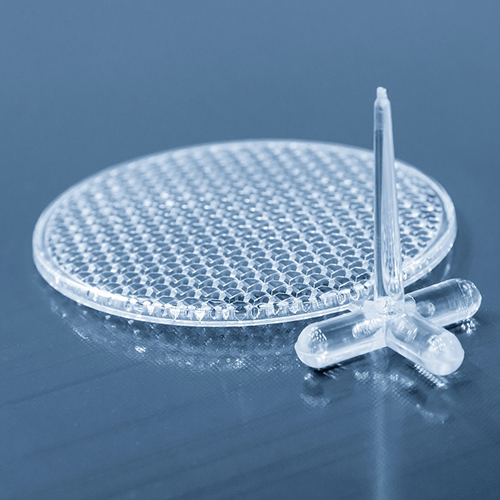

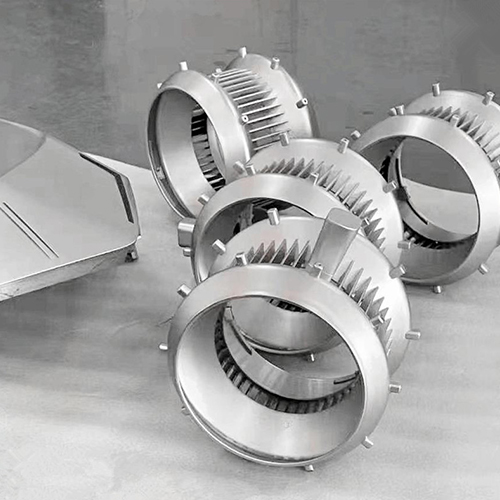

Transmission parts: including ball screws, guide rails, sliders, nut seats, support seats, couplings, etc. Linear motion parts: such as guide shafts, guide shaft supports, linear bearings and ball bushings, linear guides, ball screws, screw support seats, trapezoidal screws, etc. Mechanical custom parts: including bearings, seat bearings, retaining rings, springs, fasteners, plungers, positioning parts, operating parts, nitrogen springs, quick clamps, locating pins and precision bushings, etc. Metal or plastic housings and brackets of some mechanical parts in electric components and control systems